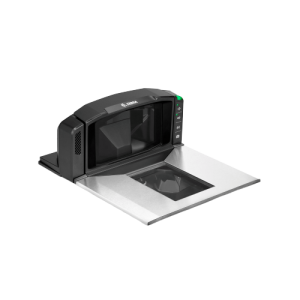

DS4600 Series for Electronics and Light Manufacturing

BUILT FOR LIFE ON THE PRODUCTION LINE

Direct part marks and high density barcodes can be tough to scan, but not with the DS4600 Series for Electronics Manufacturing. This intuitive imager has the widest decode range in its class—enabling workers to position it at a more natural distance to see the barcode or mark they are scanning.

PURPOSE BUILT INNOVATION FOR ELECTRONICS AND LIGHT MANUFACTURING

Improve productivity and quality control with the handheld scanner that’s purpose-built for electronics and light manufacturing. This versatile device can capture laser etched direct part marks, high density and low contrast codes, in addition to 4-inch wide barcodes. A built-in diffuser provides superior performance on a wide variety of surfaces, while a wide decode range enables the capture of direct part marks and high density barcodes, nearer and farther than a general purpose scanner.

ADVANCED ILLUMINATION FOR SUPERIOR PERFORMANCE

A patented rear engine design creates more room for a built-in diffuser—providing optimal illumination on a wide variety of surfaces. Indirect lighting enables the capture of marks printed on shiny and reflective surfaces, while direct light provides the bright light needed to successfully read low contrast barcodes and laser etched DPM codes on plastic and metal subcomponents.

CAPTURE EVERYTHING FROM DIRECT PART MARKS TO EXTRA-WIDE BARCODES

No matter what type of marks and barcodes are found in your electronics manufacturing operations, you can capture them all. The DS4600 Series for Electronics Manufacturing easily reads tiny and dense barcodes printed on plastic and metal subcomponents, including laser etched direct part marks. And the same imager can read 4-inch wide barcodes found on carton labels and packages.

HAPTIC AND VISUAL FEEDBACK FOR NOISY ENVIRONMENTS

On the production line, a traditional beep tone can be hard to hear. That’s why the DS4600 Series for Electronics Manufacturing offers multiple feedback modes including haptic/vibration, a good decode LED that’s visible from any position, a beep tone and Zebra’s Direct Decode Indicator that projects the illumination on the barcode.

Additional information

| Industries | Manufacturing |

|---|

6.5 in. H x 2.6 in. W x 3.9 in. D

16.5 cm H x 6.7 cm W x 9.8 cm D

COLOR

Twilight Black

DROP TOLERANCE

Designed to withstand multiple drops at 6.0 ft./1.8 m to concrete

SCANNER TECHNOLOGY

Array Imager

WEIGHT

5.7 oz. / 161.9 g

SEALING

IP52

DECODE CAPACITY

1D, 2D, PDF417

Get in touch

Please feel free to contact us with any question or concern you may have and a member of our team will reply as soon as possible. We appreciate all questions and feedback and look forward to hearing from you!